Guide to Polyethylene Packaging: Transit for Your Products

Introduction to Polyethylene Packaging

Polyethylene packaging is a versatile, durable solution widely used across industries such as electronics, automotive, healthcare, and more. Known for its superior cushioning and protective qualities, this type of packaging is crucial for ensuring the safe delivery of sensitive and high-value items. Polyethylene packaging, particularly when used in the form of polyethylene foam inserts, offers repeated, reliable protection even under conditions that involve rough handling or environmental challenges.

The Benefits of Polyethylene Packaging

- Optimal Protection and Reusability

Polyethylene packaging foam is cross-linked and designed to withstand impacts without degradation, making it perfect for multi-trip applications. Its resilience allows it to retain cushioning performance after multiple impacts, providing dependable protection for expensive or delicate products during transportation and handling. - Cost-Effectiveness for Long-Term Use

Though polyethylene packaging is slightly more costly than other materials like polystyrene, its durability and reusability make it a cost-effective choice for items that need enduring protection. Businesses that require secure transit for high-value products can rely on polyethylene packaging to ensure repeated use without compromising safety or integrity. - Chemical and Moisture Resistance

Polyethylene foam is resistant to moisture, chemicals, and temperature fluctuations, making it ideal for packaging products sensitive to these factors. Electronic devices, for example, benefit from polyethylene foam inserts that create a barrier against moisture and temperature changes, extending their lifespan and maintaining functionality during transport and storage. - Customizable and Versatile

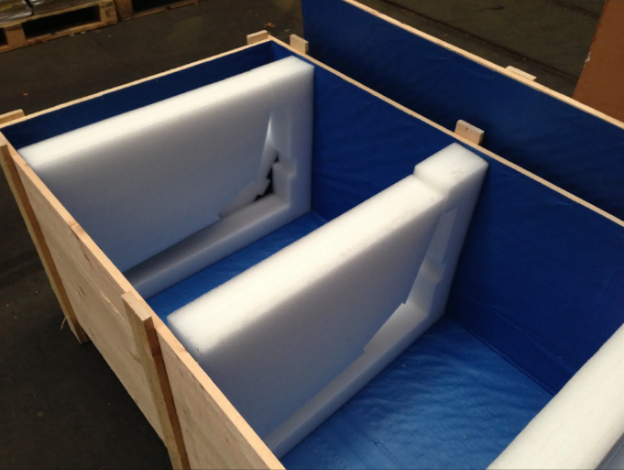

Polyethylene foam packaging is highly customizable, enabling businesses to select color combinations, specific designs, and tailored cushioning levels to meet unique product needs. It can be shaped into bespoke inserts that snugly fit products, minimizing movement and reducing the chance of impact damage. The flexibility of polyethylene foam makes it suitable for a wide range of applications, from tool packs to factory transit packaging.

Why Choose Polyethylene Packaging?

- Material Options for Specific Needs

Polyethylene packaging foam is available in several color options, including black, white, blue, and anti-static pink. Advanced PP, for instance, utilizes brands like Ethafoam, Stratocell, Jiffycell Polylam, and Nopaplank, which are known for quality and durability. The choice of these materials allows businesses to select foam types best suited for their specific packaging requirements. When shipping sensitive items like furniture along with packaged goods, working with specialists in Furniture Shipping Texas https://www.shiply.com/us/furniture-shipping/texas-furniture-shipping ensures that your logistics are optimized for both durability and precision. - Enhanced Performance with Specialized Foams

For products needing extra precision in cushioning, options like Nomafoam, Plaztazote, and Zotefoam are available. These specialized foams cater to delicate and high-value items, often utilizing advanced tooling to ensure a perfect fit. This attention to specialized materials ensures that each item receives the ideal level of protection for its unique specifications. - Complete Packaging Solutions

Polyethylene packaging providers, such as Advanced PP, also offer additional materials like boxes, cartons, bubble wrap, and tapes, creating a comprehensive packaging solution. Working with a single supplier simplifies ordering, minimizes paperwork, and helps maintain balanced stock levels. This cohesive approach guarantees that each packaging order is streamlined, efficient, and optimally tailored for each product.

Polyethylene Foam Inserts: An Innovative Solution

Polyethylene foam inserts play a pivotal role in protecting fragile products during shipping and handling. The foam’s cell structure acts as tiny shock absorbers, distributing impact forces and minimizing damage. This cushioning ability is critical for industries where products are highly sensitive to impacts, such as electronics, medical devices, and precision tools.

Polyethylene foam inserts are also excellent for multi-drop protection, which is the capability to maintain their structure and protective qualities after repeated impacts. This feature is especially valuable for products that need sustained, dependable protection over multiple trips or for factory use where products are frequently moved around.

How Polyethylene Packaging Contributes to Brand Value

- Enhanced Product Protection

The effectiveness of polyethylene packaging in preventing damage reflects positively on a brand’s commitment to quality. Clients receiving well-protected goods are more likely to trust and return to a brand, knowing that product integrity is prioritized. - Reduction in Shipping and Replacement Costs

By minimizing the chances of product damage during shipping, polyethylene foam inserts help reduce costly returns, repairs, and replacements. This impact is particularly significant for businesses with high-value or fragile products, where the cost of damaged goods can affect profit margins. - Sustainability and Efficiency

Polyethylene packaging foam’s durability and reusability contribute to eco-friendliness by reducing the need for frequent replacements. This characteristic aligns with the growing demand for sustainable packaging options and can enhance a brand’s image as environmentally responsible.

Applications of Polyethylene Packaging Across Industries

- Electronics

Polyethylene packaging foam is widely used in electronics for its ability to protect delicate components. Electronic items such as computers, phones, and other devices are prone to damage from shock and moisture. Polyethylene foam inserts offer robust protection and create a stable, moisture-resistant environment, extending the lifespan of electronic products. - Automotive

In the automotive sector, polyethylene foam inserts are used to protect small, sensitive parts that require high shock absorption during transport. This type of packaging helps prevent potential damage caused by vibrations or impacts, ensuring parts arrive in pristine condition. - Medical Equipment

Polyethylene packaging foam is crucial in the healthcare industry, where sensitive and often high-value equipment requires secure packaging. From diagnostic tools to surgical instruments, polyethylene foam inserts provide a custom fit that keeps items stable, clean, and safe during transit.

Advantages of Choosing Advanced PP for Polyethylene Packaging

- Expertise and Innovation

Advanced PP leverages extensive experience and expertise to deliver innovative polyethylene packaging solutions. The company’s specialization in custom designs, combined with materials like Ethafoam and Nomafoam, ensures clients receive high-performance packaging tailored to their specific needs. - Commitment to Quality and Customer Service

Advanced PP prioritizes customer satisfaction by providing end-to-end service, from initial design consultation to final delivery. Their team of experienced professionals understands the importance of protective packaging and works diligently to provide products that meet industry standards and client expectations. - Customized Packaging Solutions

Advanced PP designs every packaging solution with the customer’s specific product requirements in mind. Whether through custom polyethylene foam inserts or unique color combinations, the company creates packaging that not only protects but also enhances the product’s presentation.

Polyethylene Foam: Key Considerations for Businesses

- Understanding Product Needs

Selecting the right type of polyethylene foam insert involves analyzing the product’s requirements. For instance, high-value or fragile items may benefit from advanced foams like Zotefoam or Plaztazote, which offer superior cushioning and durability. - Cost-Effectiveness in Long-Term Packaging

While polyethylene packaging may have a higher initial cost, its longevity and reusability offer a favorable return on investment, especially for products needing multi-trip protection. Businesses should weigh these benefits against the initial expenditure to understand the long-term savings associated with polyethylene packaging. - Efficiency in Logistics and Stock Management

Sourcing polyethylene packaging from a single supplier like Advanced PP ensures streamlined logistics. This efficiency minimizes stock imbalances, simplifies the ordering process, and provides consistent quality across each shipment, essential for businesses looking to optimize supply chain operations.

Read Also: Acoustic Barriers: Enhancing Sound Insulation in Various Applications

Conclusion

Polyethylene packaging, especially in the form of polyethylene foam inserts, is an essential tool for industries focused on protecting valuable and delicate products. Its resilience, reusability, and ability to provide consistent protection make it an ideal choice for businesses prioritizing safety and cost-effectiveness. With its capability to withstand environmental factors like moisture and temperature changes, polyethylene packaging delivers unmatched performance in safeguarding goods across various industries.

For businesses in need of reliable and high-quality protective packaging, polyethylene foam is a powerful solution that guarantees product safety and customer satisfaction. By choosing polyethylene packaging, companies can ensure that their products remain secure, protected, and ready for customers, thereby enhancing brand trust and reducing costly damages.