Acoustic Barriers: Enhancing Sound Insulation in Various Applications

Acoustic barriers are essential products designed to minimize airborne noise and impact sound transmission. These sound-insulating solutions are crucial in various settings, from industrial applications to residential environments. With a focus on reducing sound transmission and improving comfort, acoustic barriers are engineered to provide excellent vibration dampening and thermal insulation. This article will delve into the various types of acoustic barriers available, their applications, benefits, and how they contribute to effective sound management across diverse industries.

Understanding Acoustic Barriers

What Are Acoustic Barriers?

Acoustic barriers are flexible sound-insulating products that aim to reduce airborne noises and provide insulation against impact sounds. Their primary function is to prevent sound transmission loss, making them vital in environments where noise control is necessary. These barriers can be made from various materials, including polymeric, bitumen, and foam, each with specific properties suited to different applications.

Key Features of Acoustic Barriers

- Sound Insulation: Acoustic barriers significantly reduce noise levels, providing a more comfortable environment in both commercial and residential settings.

- Vibration Dampening: In addition to sound insulation, these products also serve as excellent anti-vibration pads, reducing impact sounds from machinery or other sources.

- Thermal Radiation Reflection: Many acoustic barriers are designed to reflect thermal radiation, making them suitable for use in applications where heat management is essential.

- Customization: Acoustic barriers can be supplied in sheets, die-cut, or water jet-cut to meet specific requirements, allowing for application on curved or irregular surfaces.

Types of Acoustic Barriers

Polymeric Acoustic Barriers

Polymeric acoustic barriers, such as the C03 and C09 models, are low-density vinyl membranes designed to enhance sound insulation across various frequencies. These barriers are made from naturally occurring materials and are free from lead and unrefined oils. Their effective design allows them to address resonance issues in lightweight composites, such as plywood.

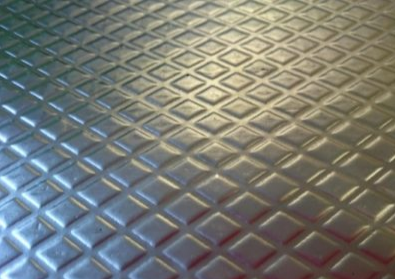

Bitumen Acoustic Barriers

Bitumen-based acoustic barriers, like the C022 and C023 models, come with self-adhesive backing and a PE foil covering to prevent seepage from the bitumen. These barriers excel at preventing sound transmission and vibration, making them ideal for flat sound insulation applications. The C024 model, featuring an aluminum foil surface, is particularly effective in areas exposed to heat, such as engine compartments in vehicles.

Foam Acoustic Barriers

Foam barriers offer unique sound absorption properties, with options such as the Class 0 foam providing exceptional fire resistance and sound insulation. This type of foam is flexible, allowing for easy application to various shapes and surfaces, making it suitable for industrial and automotive applications.

Applications of Acoustic Barriers

Acoustic barriers find use in numerous sectors, including:

- Automotive Industry: They are employed in vehicles to reduce engine noise and improve passenger comfort.

- Home Appliances: Used in white goods to minimize operational noise.

- Construction: Acoustic barriers are installed in lift cabins and around machinery to control sound levels.

- Marine Applications: They dampen noise in marine engines and on boats, enhancing comfort for passengers.

- Industrial Equipment: Barriers are applied to machinery to lower noise emissions and vibrations.

Benefits of Acoustic Barriers

1. Improved Comfort and Quality of Life

By significantly reducing noise levels, acoustic barriers enhance comfort in residential and commercial spaces. They create a quieter environment, which is especially beneficial in urban areas with high noise pollution.

2. Enhanced Productivity

In workplaces, reduced noise levels contribute to higher productivity by minimizing distractions. Employees can focus better when they are not constantly exposed to disruptive sounds.

3. Increased Property Value

Properties equipped with effective sound insulation measures often have a higher market value. Buyers appreciate the added comfort and quiet, making these features attractive selling points.

4. Versatility

Acoustic barriers can be customized to fit various applications, from automotive to industrial settings. This adaptability allows businesses to implement effective sound management solutions tailored to their specific needs.

5. Environmentally Friendly Options

Many acoustic barriers are made from recycled or eco-friendly materials, contributing to sustainability efforts. This approach aligns with the growing demand for environmentally responsible products in various industries.

Read Also: LED Lighting Telford: Enhancing Energy Efficiency and Sustainability

The Foam Conversion Process

What is Foam Conversion?

Foam conversion involves processing foam into products that meet specific requirements. This process can include cutting, moulding, and laminating foam materials to create tailored acoustic solutions. Various foam types, such as polyurethane, polystyrene, and polyethylene, can be converted for different applications.

Techniques Used in Foam Conversion

- Cutting: Foam is cut into precise shapes using techniques like hot wire cutting and water jet cutting.

- Moulding: Foam can be moulded into unique forms to suit particular needs.

- Laminating: Combining different foam layers or bonding foam to other materials enhances product properties.

- Die Cutting: This method allows for high-volume production of specific shapes.

Applications of Foam Conversion

Foam conversion finds applications in various industries, including:

- Packaging: Custom foam packaging protects delicate items during transportation.

- Seating and Cushions: Foam is shaped for use in furniture and automotive interiors.

- Insulation: Foams are used for thermal and sound insulation in construction projects.

- Medical Products: Foam is converted to create medical cushions and supports.

- Automotive Components: Custom foam products are developed for interior applications, contributing to comfort and insulation.

Conclusion

Acoustic barriers play a crucial role in managing sound in a variety of settings. Their ability to reduce noise transmission and dampen vibrations makes them essential in both residential and industrial applications. With the versatility of products like polymeric, bitumen, and foam barriers, businesses can effectively address their sound management needs.

Moreover, the foam conversion process allows for the creation of customized solutions, ensuring that each product meets the specific requirements of its application. As industries continue to seek innovative ways to enhance comfort and efficiency, acoustic barriers will remain a vital component of sound management strategies.

For further inquiries about acoustic barriers and foam conversion products tailored to your needs, do not hesitate to contact Acoustafoam. Their dedicated team is ready to assist you in finding the perfect solution for your acoustic challenges.