Biaxial Definicion: Understanding Its Role in Science and Engineering

In both scientific and industrial contexts, understanding the behavior of materials under stress is essential to designing reliable and safe systems. One frequently encountered term in this field is “biaxial.” When paired with the word “definicion”—meaning “definition” in Spanish—the phrase “biaxial definicion” refers to the fundamental explanation of how certain materials or systems behave when subjected to forces in two directions.

This article offers an in-depth look at the concept of biaxial stress, its significance in engineering and materials science, and how understanding the biaxial behavior of materials enhances innovation across industries.

What Does Biaxial Mean?

The term biaxial is derived from the Latin prefix bi- meaning “two,” and the word axial, relating to an axis. Hence, biaxial literally refers to something having or relating to two axes. In mechanical and structural engineering, biaxial typically describes a condition where a material or structure is subjected to stress or force along two perpendicular directions within a single plane.

In contrast to uniaxial stress, which acts in only one direction, biaxial stress allows engineers to better understand how materials perform in real-world applications where forces rarely act along a single line. Examples include pressure on a circular membrane, tension on a plastic film, or forces in bridge decks.

Biaxial Definicion in Material Science

When we talk about “biaxial definicion” in the context of materials science, we refer to the systematic explanation of how a material behaves when force is applied along two axes. In practical terms, this means evaluating how a sheet of metal, polymer, or composite deforms, stretches, or fractures when simultaneously pulled or compressed in two directions.

Understanding this behavior is crucial for:

- Designing packaging materials like plastic films.

- Creating durable medical devices such as stents or flexible tubing.

- Engineering metal components for aircraft or automobiles.

Materials tested under biaxial stress conditions often exhibit different mechanical properties compared to when tested under uniaxial loads. These variations are crucial to consider during product development.

See also: Water Bottle with MagSafe: The Smart Way to Stay Hydrated

Applications of Biaxial Testing

To achieve a reliable biaxial definicion, many industries rely on specialized biaxial testing methods. These tests are designed to simulate real-world stress conditions. Below are some major application areas:

1. Biomedical Engineering

Artificial heart valves, stents, and skin grafts undergo biaxial testing to ensure they can withstand bodily forces from multiple directions. Human tissues, such as skin and arteries, also naturally experience biaxial stress.

2. Aerospace and Automotive

In these industries, materials used in wings, fuselages, or structural panels experience complex load paths. Understanding biaxial behavior helps engineers predict fatigue, failure, and deformation.

3. Civil Engineering

Bridge decks, concrete slabs, and geosynthetic materials like geogrids are subjected to multidirectional forces. Biaxial analysis helps ensure safety and longevity.

4. Plastic Film and Packaging

Films used in food packaging or medical wraps often undergo biaxial stretching during manufacturing to improve their clarity, strength, and flexibility.

Types of Biaxial Testing

To accurately define how a material behaves under biaxial loads, several test configurations are employed:

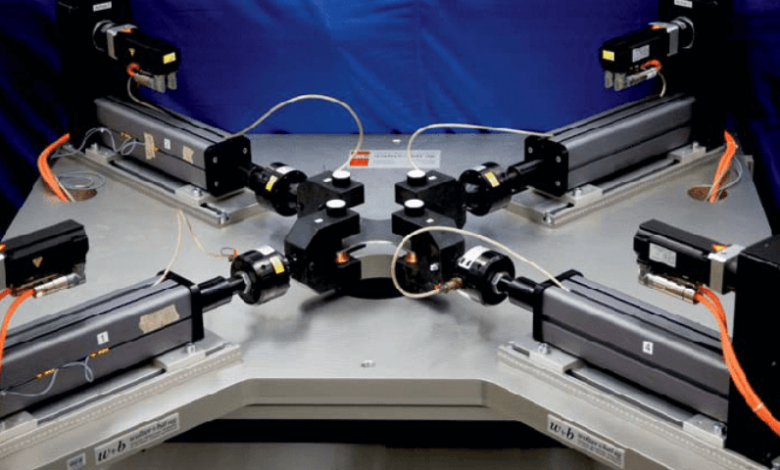

a) Biaxial Tensile Testing

A specimen, usually a square film or sheet, is pulled along two perpendicular axes. This is the most common method and helps evaluate strength, elasticity, and failure points.

b) Bulge Testing

A thin material is clamped over a circular opening and pressurized until it bulges. This mimics biaxial tension similar to what a balloon experiences when inflated.

c) Biaxial Compression Testing

Less common, but used for evaluating how foams, soils, or other compressible materials behave under two-dimensional compressive forces.

Each method yields crucial data on stress-strain relationships, which are then used to build mathematical models and simulations.

Importance of Understanding Biaxial Properties

Incorporating the concept of biaxial definicion into design and testing processes offers multiple benefits:

Improved Product Performance

Understanding biaxial behavior ensures that products such as membranes, films, or tires can endure real-life multidirectional stresses without failure.

Increased Safety

Structures such as bridges or aerospace components rely on biaxial data to avoid catastrophic failures under unpredictable load conditions.

Material Optimization

With precise biaxial analysis, manufacturers can choose or develop materials that offer high strength-to-weight ratios, reducing costs and environmental impact.

Innovation

Biaxial studies enable the development of new materials like smart textiles or flexible electronics that require reliable performance under bending and stretching.

Challenges in Biaxial Analysis

Despite its importance, conducting and interpreting biaxial tests is more complicated than uniaxial tests. Some of the challenges include:

- Equipment Complexity: Biaxial testing machines are sophisticated and expensive.

- Specimen Preparation: Maintaining consistent thickness and dimensions is difficult, especially for soft or flexible materials.

- Data Interpretation: Results from biaxial tests are often nonlinear and require advanced computational modeling to interpret correctly.

Despite these challenges, ongoing research and innovation continue to improve testing techniques and material modeling.

Real-World Examples

Several materials and products undergo biaxial design validation. Examples include:

- Geomallas (Geogrids): Used for reinforcing roads and soil, these materials experience biaxial tension under load.

- Touchscreen Devices: Flexible screens are subjected to complex stress states including biaxial stretching.

- Pressure Vessels: Tanks and balloons are designed to withstand biaxial stress caused by internal pressure.

Conclusion

The term biaxial definicion goes beyond a simple dictionary meaning. In scientific and engineering disciplines, it represents a foundational concept for analyzing and improving the behavior of materials under multidirectional forces. Whether in the development of robust infrastructure or high-performance consumer products, understanding the biaxial properties of materials enables better designs, safer systems, and more durable outcomes.

As materials science continues to evolve, the study and application of biaxial behavior will remain a cornerstone of innovation and engineering excellence. From aerospace to medical devices, the principles behind “biaxial definicion” are driving tomorrow’s technology.